-

E-mail: scfpumps@gmail.com

Products

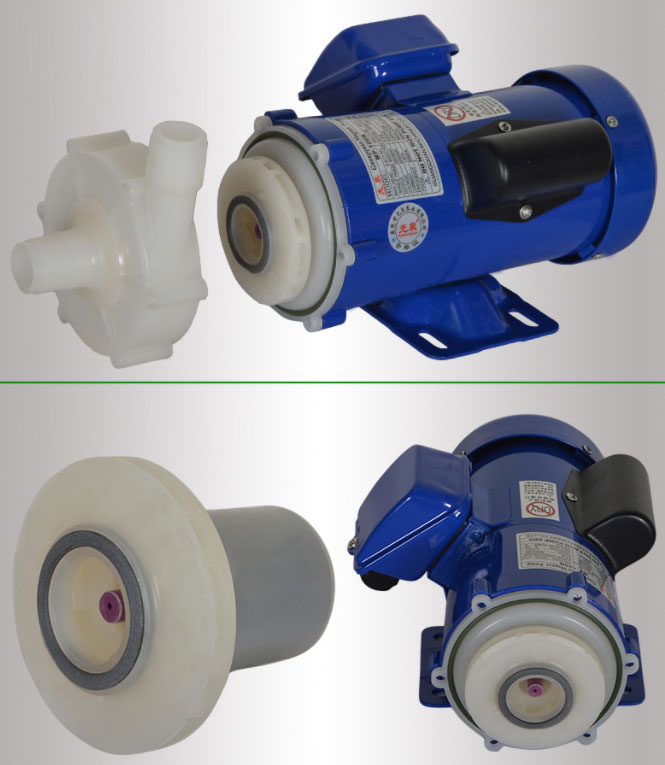

High Temperature And Corrosion Resistant Fluoroplastic Magnetic Drive Pump

Fluoroplastic magnetic drive pump is a high-tech product that applies the working principle of permanent magnet coupling to centrifugal pump.

The flow-passing parts of the fluoroplastic magnetic pump are all made of fluoroplastic, with reasonable design, advanced technology, full sealing and no leakage.

The flow part of the plastic magnetic drive pump is made of fluoroplastic alloy, which can continuously transport any concentration of acid, alkali, strong oxidant and other corrosive media.

The design of the fluoroplastic magnetic pump not only has the advantages of compact structure, beautiful appearance, small volume, low noise, and reliable operation of ordinary magnetic pumps, but also its flow-passing parts are all made of the best corrosion-resistant "plastic king" in the world.

Therefore, the fluoroplastic magnetic pump can transport corrosive media such as acids, alkalis, and oxidants of any concentration (strong) without damage.

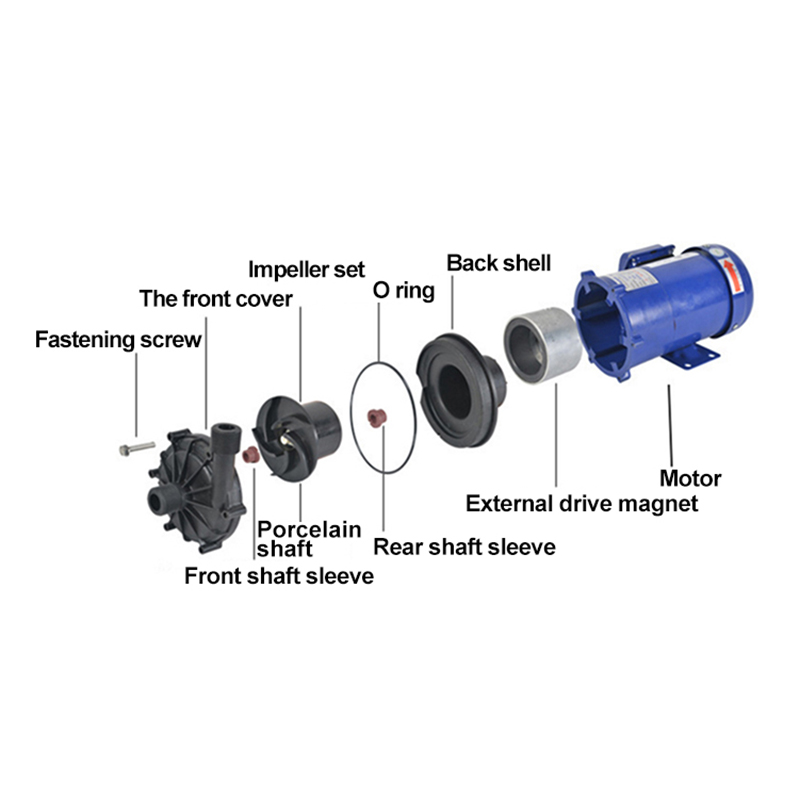

Fluorine plastic magnetic pump is a kind of chemical process pump that applies the principle of modern magnetic mechanics and uses permanent magnets to realize non-contact indirect transmission. When the motor drives the outer magnetic steel assembly to rotate, the magnetic line of force through the magnetic field passes through the isolation sleeve to drive the inner magnetic steel assembly and the impeller to rotate synchronously, and the medium is completely enclosed in the stationary isolation sleeve, so as to achieve the purpose of pumping the medium without leakage. It completely solves the shaft seal leakage of the mechanical transmission pump, and is a new type of industrial pump with full sealing, no leakage and no pollution. Fluoroplastic magnetic pump is an ideal pump to eliminate running, popping, dripping and leaking in the chemical process, eliminate environmental pollution, create "no-leakage workshop" and "no-leakage factory", and realize safe and civilized production.

Strong wear resistance

Acid and alkali resistance

Good sealing

High stability

Strong magnet

High quality magnet, durable, low noise

Pump housing

Sophisticated design, beautiful appearance, acid and alkali resistance, special for chemical industry

Energy-saving motor

High temperature and corrosion resistance, energy saving and power saving, long service life

PVDF pump head made of fluoroplastic

Fluoroplastics have excellent dielectric properties, chemical corrosion resistance, high and low temperature resistance, waterproof, non-stick, low friction coefficient, good self-lubrication and other properties.

Working principle: Fluorine plastic magnetic pump consists of three parts: pump, magnetic drive and motor. The key component, the magnetic drive, consists of an outer magnetic rotor, an inner magnetic rotor and a non-magnetic isolation sleeve. When the motor drives the outer magnetic rotor to rotate, the magnetic field can penetrate the air gap and non-magnetic substances, and drive the inner magnetic rotor connected to the impeller to rotate synchronously, realizing the non-contact transmission of power and converting the dynamic seal into a static seal. Since the pump shaft and internal magnetic rotor are completely sealed by the pump body and the isolation sleeve, the problems of "running, leaking, dripping, and leaking" are completely solved, and the physical and mental health of employees and safe production are effectively guaranteed.

The magnetic drive pump body is completely sealed, and there is no shaft seal design, which will not cause leakage of chemical liquid.

For transportation process, electroplating, chemical industry, dyeing, waste water, waste gas treatment, etc.

Back shell

The front cover

Impeller pack seal O ring

Fastening screw

Porcelain shaft

Rear shaft sleeve

Front shaft sleeve

motor

External drive magnet