The electroplating process includes filtering the chemicals and circulating them through a tube. The anodizing process includes circulating dyes and sealants. Both processes include acid surface treatment and transfer of chemicals from drums to tanks. Chemical resistant pumps provide the durable construction required for these operations.

Plating wastewater is mainly concentrated from water for cleaning plated parts, waste plating solution, brushing pole plate wastewater and equipment cooling water, etc. Electroplating wastewater is usually toxic or corrosive liquid such as cyanide-containing wastewater, nickel-containing wastewater and heavy metal wastewater. In the process of electroplating wastewater treatment, according to the actual working conditions, flow rate, head, power, caliber, medium temperature, concentration and other parameters, flexible selection of suitable engineering plastic corrosion resistant pumps.

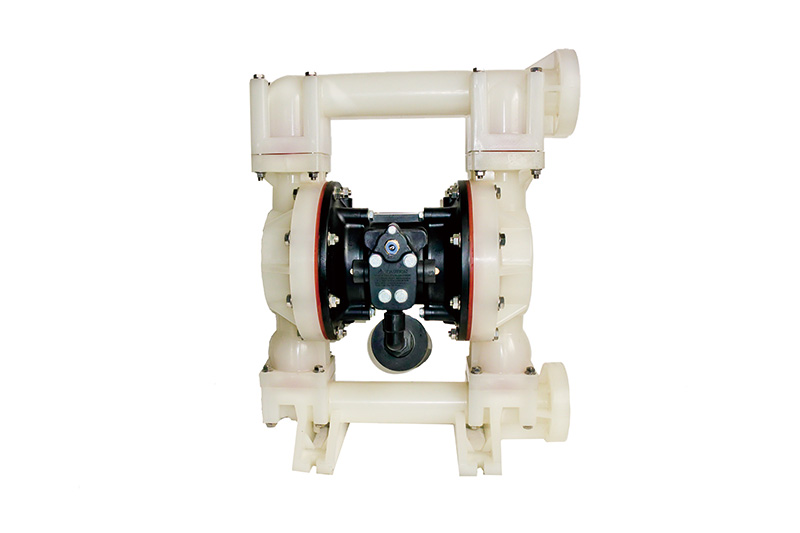

ZhiJing series commonly used in the Plating industry

Magnetic Drive Centrifugal Pump is suitable for pumping and circulating all clean chemical water containing acid and alkali components.

Chemical vertical pumps are used for lifting, conveying and circulating liquids. It is used to pump out water by centrifugal force generated by the impeller driven by the rotation of the motor.

Diaphragm pumps can pump both flowing liquids and some media that do not flow easily, and viscous liquids, or liquids that contain impurities. Also has a unique self-priming ability, so it is also very widely in use.

Chemical liquid filter is generally used in the industrial production process, acidic and alkaline solution solid-liquid filtration and separation use. It is generally made of PP/PVDF/PVC plastic injection, and can be used to filter a variety of chemical liquids.

Post time: Dec-22-2022